Mandible Cutting Guide

| Start Date | End Date | Client | Supervisor | Location |

|---|---|---|---|---|

| 09/2018 | 04/2019 | Dr. Eitan Prisman | Prof. Antony Hodgson | Vancouver, Canada |

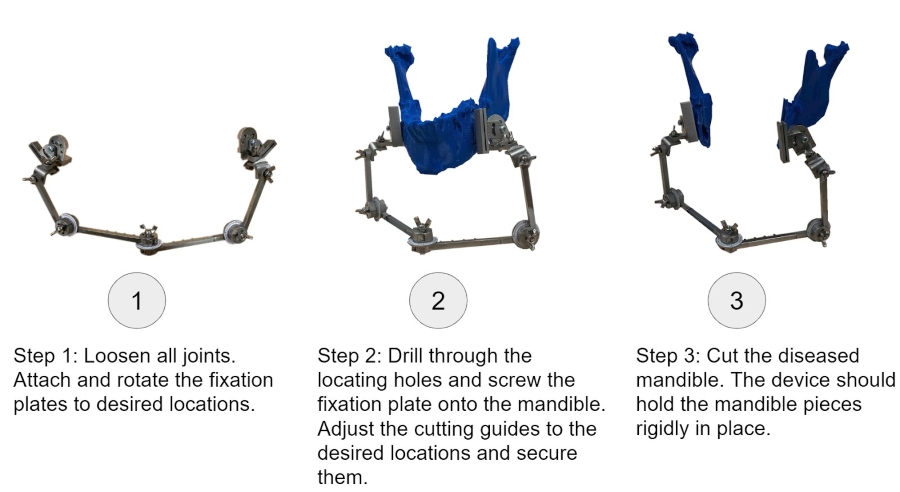

Workflow of the Device

Project Description

Patients with mandible cancer sometimes need to receive mandible reconstruction surgery (*Mandible is the lower jaw of a human). Before we conduct our project, the surgery is being performed using a 3D printed cutting guide. However, the lead time of modelling and printing is long which allows the aggressive tumor to grow. Also, after part of the mandible is resected, the two free mandible pieces can move freely relative to each other causing problems for the reconstruction later. Therefore, it is necessary to design an adjustable and reusable surgical tool that can guide the cuts and constrain the mandible pieces relative to each other as well as fit a wide patient population.

In a four-member team, we designed and built an adjustable and reusable mandible cutting guide that fit all those needs. In order to ensure the adjustability and rigid fixation, we made several design iterations and tested them with 3D printed and machined prototypes. After reaching out to a specialist in medical device design, we managed to build the final prototype at a relatively low cost with good enough quality to prove the functionality. Preliminary analysis of device usability was conducted by use case testing on surgeons and associates at Vancouver General Hospital. Most of the participants reflected that our device is easy to use. The client, an otolaryngologist, is satisfied with the results and the project will be further developed by other teams.

My Main Contributions

- Transferred client’s needs to design requirements through weekly meeting with the client.

- Designed and conducted rapid prototyping and testing to ensure adjustability and rigid fixation.

- Outreached specialist in medical device design and gathered useful advices and manufacturing resource.

- Developed the 3D assembly and manufacturing drawings using SolidWorks, and fabricated the prototypes using 3D printers, a lathe, a milling machine, a waterjet, and a laser welder.

- Transferred client’s needs to design requirements through weekly meeting with the client.